TROCELLEN® is one of the leading manufacturers of chemically and physically cross-linked polyolefin foams and combines its skills in the foam production with various converting capabilities. Together with our partners, we realize innovative applications and solutions that meet the requirements of the automotive industry. Our focus is on the development of thermoformed air ducts for the automotive industry. Our in-house developed twinsheet thermoforming process has proven itself in our products for years and has established itself on the market.

Our tailored solutions with sustainable customer value are the result of our longtime experience combined with our passion for automobiles.

Optimized material xlpe foam

Heat resistance up to 140°C

Low burning rate (fmvss 302) < 100 mm/min

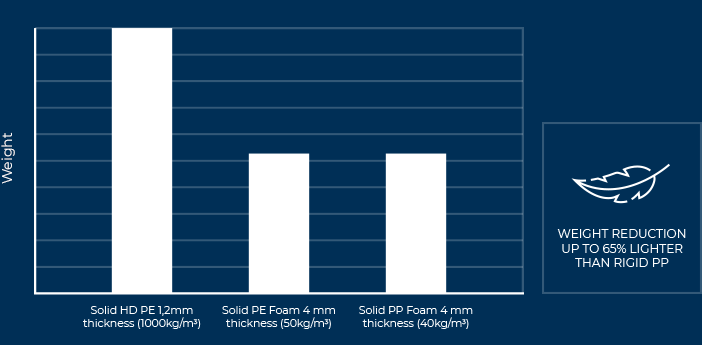

Up to 65% weight saving

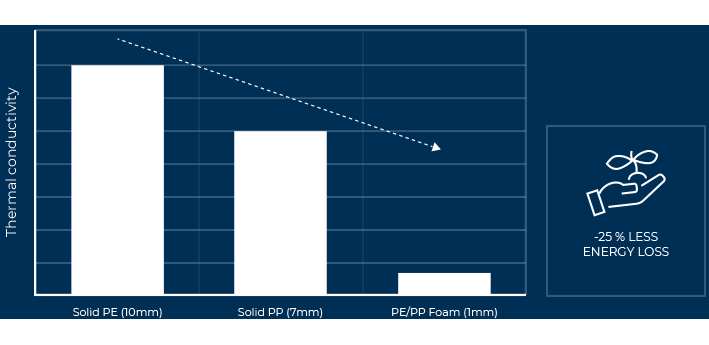

Thermal insulation reducing energy losses

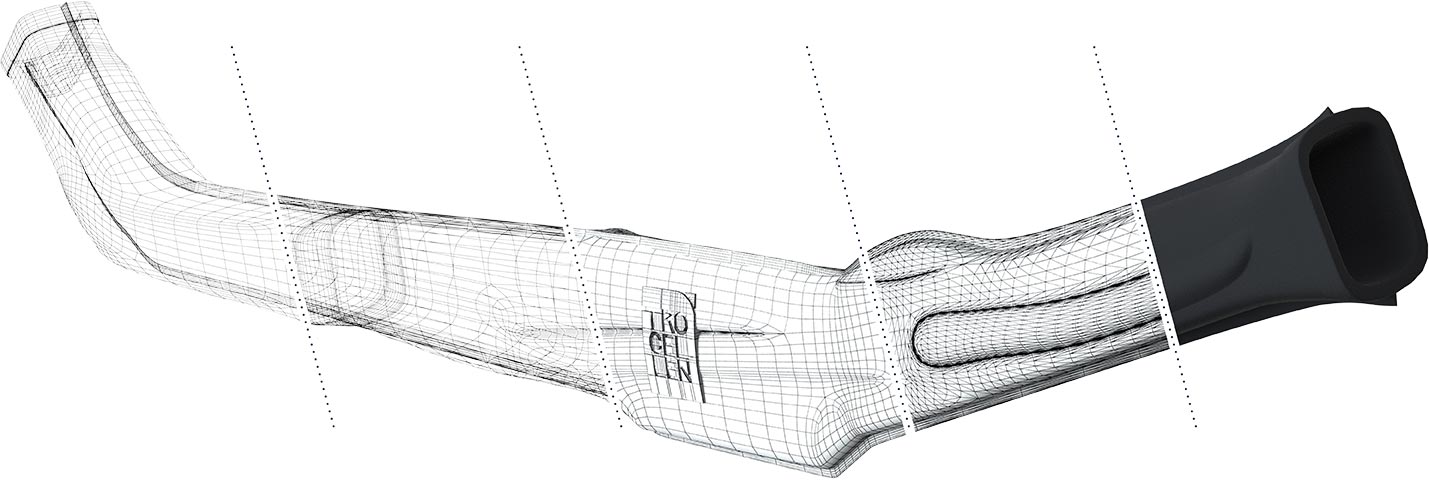

The twinsheet thermoforming process using cross-linked PO foam was developed by TROCELLEN and has proven itself as a technically and commercially attractive alternative to the conventional blow molding process for the production of air ducts.

TROCELLEN’s distinguished know-how and in-depth customer support regarding optimal material choice and process parameters in combination with the company’s perfectly suited cross-linked PO foams have made TROCELLEN the preferred partner for manufacturers of serial twinsheet air ducts as well as car manufacturers. TROCELLEN represents innovation & development - Our products are constantly developed and improved in order to always offer our customers the maximum in quality and actuality.

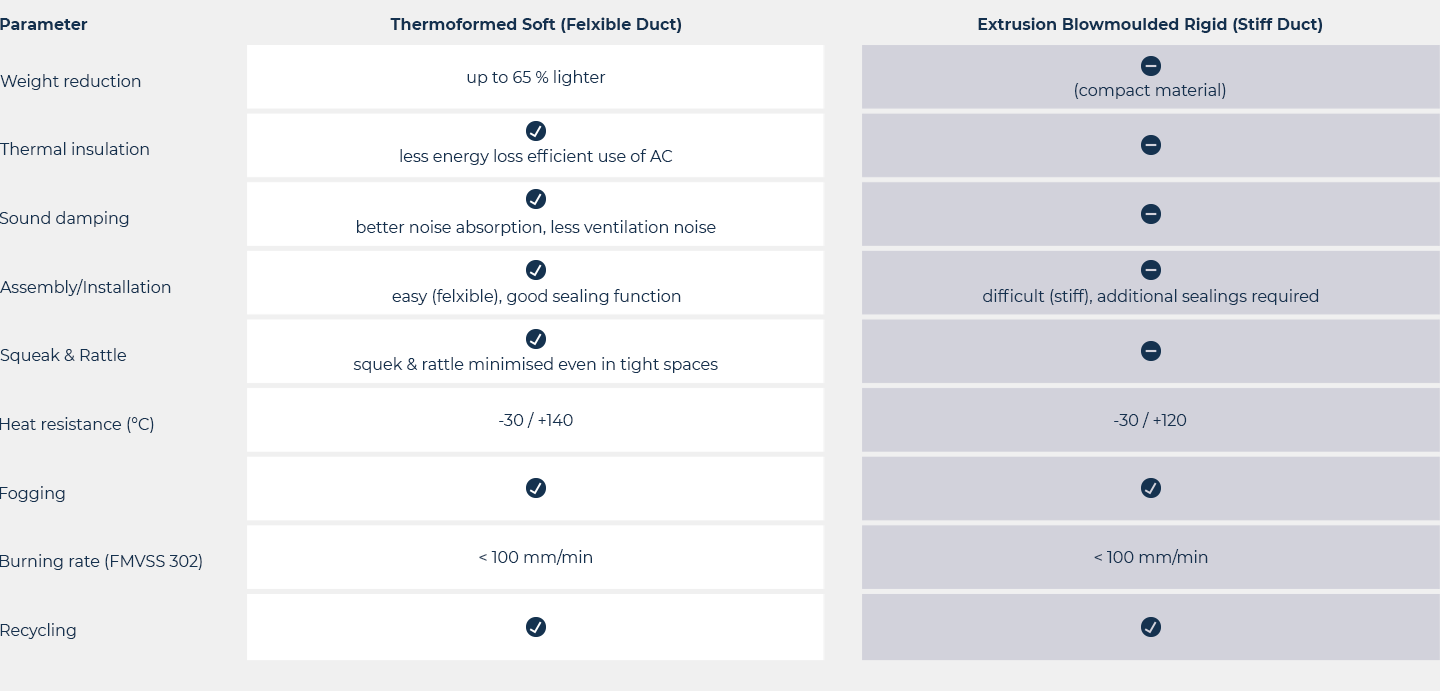

Due to the properties of the closed cell PO foam, the air ducts show excellent advantages compared to blow molded ducts:

Not sure which materials to use? Our team of experts is there to help you. Together we will find the perfect solution for you. Please do not hesitate to contact us by phone.

With our innovative materials we meet the increasing demands for lightweight solutions to reduce CO2 emissions.

Go to die cutting

Fine cell structure and a relatively hard-wearing surface characterize our chemically cross-linked PO foams

Go to chemically cross-linked foam

A very fine cell structure and a smooth surface are the properties of our physically cross-linked PO foam

Go to physically cross-linked foam