With our innovative materials, we meet the increasing demands for lightweight solutions to reduce CO2 emissions. Die-cut parts from TROCELLEN are lightweight and at the same time provide excellent acoustic and thermal insulation capabilities as well as convenient haptics. With these convincing properties, they are used for applications like sealings, seat reinforcement or fender insulation.

TROCELLEN is using a large variety of converting capabilities to get the best performance out of our materials. We supply customers with functional parts, interior trim and material & process solutions

Lightweight

Closed cell structure

Flexibility

No squeak & rattle

Impact resistance

Good compression stress

TROCELLEN's advantage lies in the combination of various converting capabilities with the production of foams. This gives us the opportunity to find the optimal solution for every requirement of our customers. Thus, together with our partners, we implement innovative applications and solutions that meet the highest standards of the automotive industry.

Sealings

Gaskets, closings and plugs made of TROCELLEN PO foam are used in instrument panels, headliners, door panels and trim structures as a wet and dry boundary sealing.

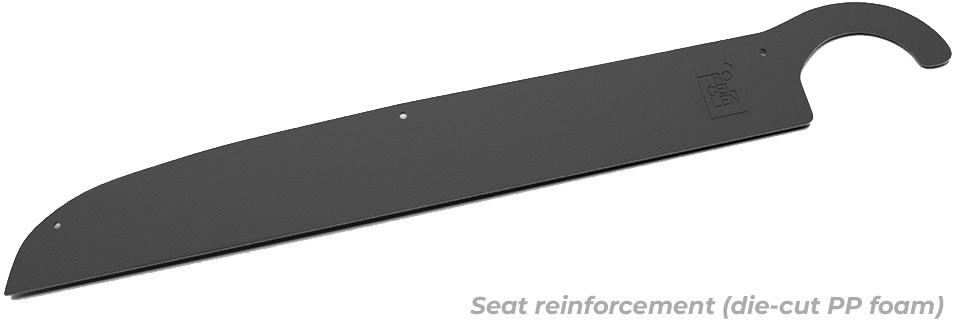

Seat reinforcements

Used within the seat cushion for the stabilisation of the PU foam.

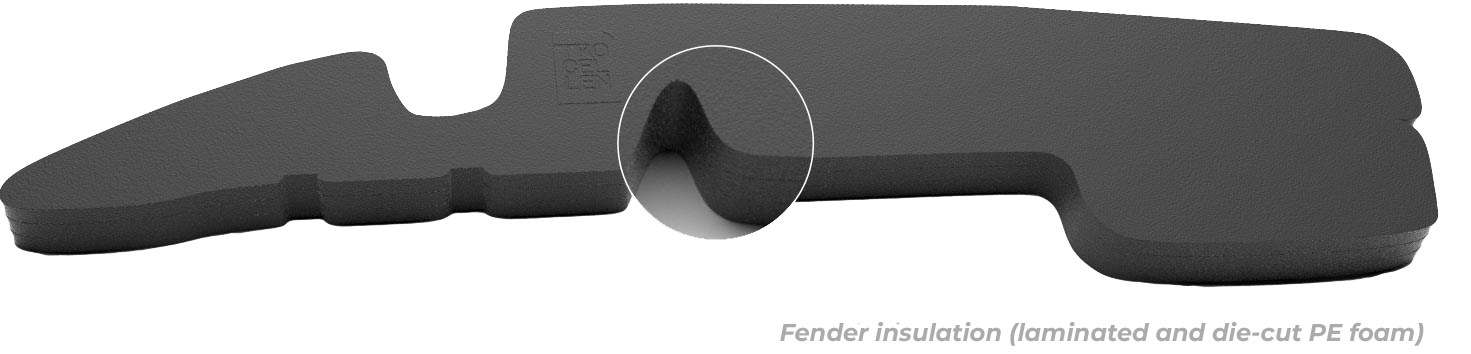

Fender insulation

Fill empty spaces in order to reduce noise effects as well as squeak & rattle.

Others

The wide range of processing techniques enables us to find the optimal solution for virtually all applications. Please do not hesitate to contact us to discuss your requirements.

In addition to our PO foams, we have a wide range of materials that we process to provide our customers with an optimal solution for their applications. Below, you will find a small selection of the materials we process:

PUR foams

Nonwovens

Thin aluminium sheets

Silicone and PVC foams

Felts

EPDM foams

Adhesives

Plastic films

Others on request

Not sure which materials to use? Our team of experts is there to help you. Together we will find the perfect solution for you. Please do not hesitate to contact us by phone.

TROCELLEN® is one of the leading manufacturers of chemically and physically cross-linked polyolefin foams ...

Go to thermoforming

Fine cell structure and a relatively hard-wearing surface characterize our chemically cross-linked PO foams.

Go to chemically cross-linked foam

A very fine cell structure and a smooth surface are the properties of our physically cross-linked PO foam.

Go to physically cross-linked foam