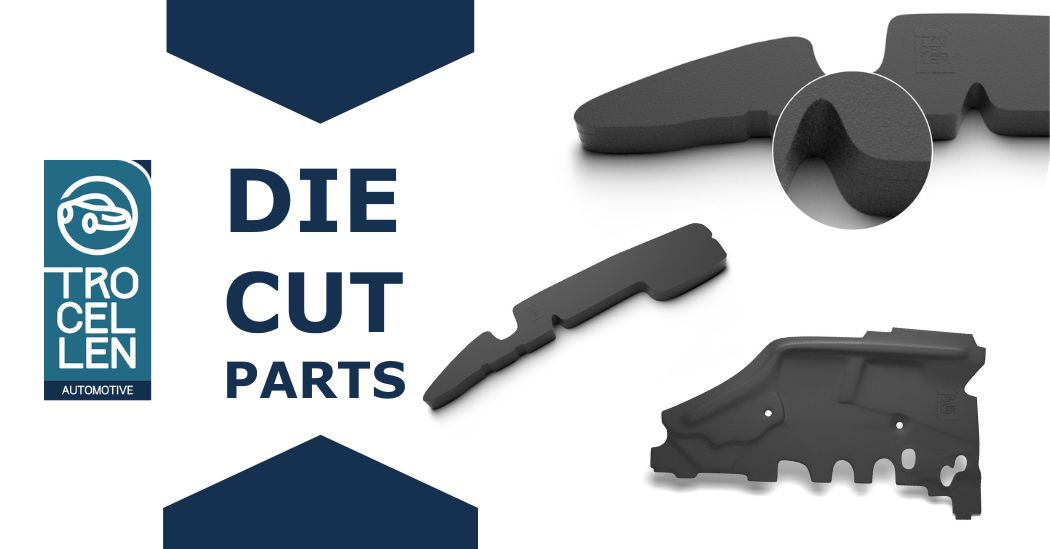

Die-cut parts play a significant role in the automotive industry, with a focus on sustainability and the benefits that come with it. Die-cut parts are widely used for sealing, seat reinforcements, wheel arch liners, and other applications in the automotive industry. The process of die-cutting involves cutting, bending, and forming metal sheets into specific shapes, which is why these parts are strong and durable.

One of the biggest advantages of die-cut parts in the automotive industry is their sustainability. The use of die-cutting helps reduce waste, as they are produced from a single metal sheet, reducing the amount of scrap material generated during production. Additionally, all parts can be recycled, making the automotive industry more environmentally friendly.

They also offer cost savings, as they can be produced quickly and efficiently, reducing the production time of a vehicle. This, in turn, reduces the overall cost of the vehicle, making it more accessible to consumers. Furthermore, die-cutting offers improved functionality and performance, as they are designed to meet specific requirements and can withstand high levels of stress and wear.

In conclusion, die-cutting parts play a critical role in the automotive industry, with a focus on sustainability and the benefits it brings. They are used for a variety of applications, including sealing, seat reinforcements, wheel arch liners, and other applications. They offer improved functionality, cost savings, and sustainability, making them an essential component of the automotive industry.

Magic happens when two people of the same field or profession have a chat. They skip the small talk and dive right away into talking about their passion—right away!

Are you attending the same events? Are you interested in similar topics? Let’s have a chat!