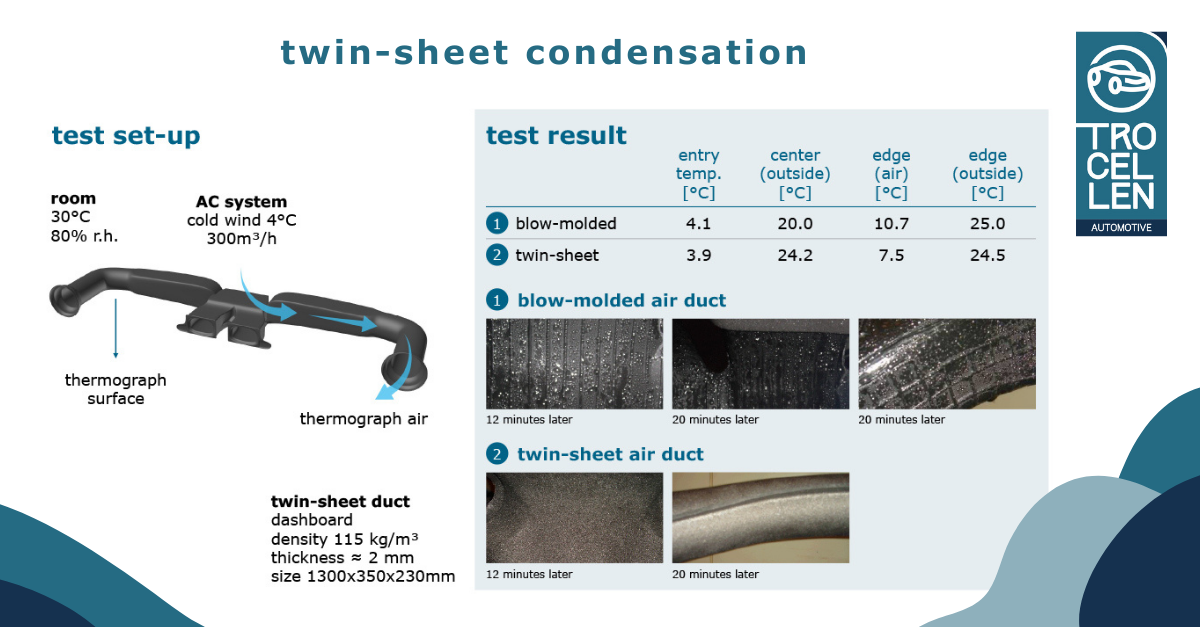

Due to the continuous development of our processes in the field of air ducts, we are able to completely avoid the condensation that occurs in the air duct. In direct comparison to conventional blow-molded air ducts, the advantage of no condensation is clearly visible.

Our own tests show a high level of condensation in conventional air ducts even after 12 or 20 minutes. In contrast, our twin-sheet air duct is dry throughout. This means that the absence of water deposits also prevents bacterial strains from settling in the area of air conditioning systems, for example, and thus also contributes to the health of the vehicle occupant. In addition, a fast drying phase also contributes to an increased longevity of the air duct.

However, our service is just as flexible as our air dutcs. In addition to the twinsheet thermoforming process developed and favored by us, we naturally also offer our customers the production of foam blow-molded air ducts. As a leading manufacturer of chemically and physically cross-linked polyolefin foams, we combine our expertise in foam production with various finishing options - always customized to meet your specific needs.

In addition, our air ducts score highly in a whole range of other benefits such as weight savings, extreme flexibility and significantly improved sound insulation. Progress towards sustainability is very important to us in our products.

Are you interested? A clear advantage for our customers is the cost-effective construction of prototypes for their individual concerns. We like to convince with quality. Convince yourself and give us a call. For more information about our air guide solutions, please contact us here.

Magic happens when two people of the same field or profession have a chat. They skip the small talk and dive right away into talking about their passion—right away!

Are you attending the same events? Are you interested in similar topics? Let’s have a chat!